Simple machines make work easier by multiplying, reducing, or changing the direction of a force. There are six different types of simple machines, including ramps, levers, and gears.

Simple Machines Science Projects

Make a Lever

A lever is a type of simple machine. You can make one and experiment with how moving the pivot point, or fulcrum, changes the way the lever can lift things.

What You Need:

- A sturdy wooden ruler, piece of foam board, or thin piece of wood (we used a 24” piece of basswood, which can be purchased at a craft store)

- A large binder clip

- Weights or variety of objects (or small paper cups and pennies to use as weights)

What You Do:

1. Remove the metal clips from the base of the binder clip by squeezing the sides together and fitting the ends through the groove.

2. Set the lever (ruler, foam board, or wood) over the binder clip. Position it near the middle so that the board is balanced. The binder clip is called the fulcrum, which gives your lever a pivot point.

3. Place a weight on one end and note what happens to each end of the lever.

4. Move the fulcrum (binder clip) closer to the end with the weight.

5. Place a lighter weight or object on the other end. If nothing happens, adjust the position of the binder clip (fulcrum) until the heavier end is raised up.

6. You have just made a lever and used it to lift a heavy object with a lighter one!

7. You can experiment more by moving the fulcrum and changing the placement of the weights.

What Happened:

In this experiment, you took a basic ruler or piece of wood and added a fulcrum to make a simple machine called a lever!

To understand how a lever works – picture a playground see-saw. With the heavier object on one end, the lighter (empty) end of the lever was raised up.

By moving the fulcrum closer to the heavy end, you were able to use the lever to help you raise the heavier object when you placed a lighter one on the opposite end.

This didn’t change anything about the lighter weight – it stayed exactly the same. Moving the lever’s pivot point closer to the object you were trying to lift changed how much force (or work) it took to lift the object. Moving the fulcrum closer to the object made it much easier to lift a heavy object.

What do you think would happen if you moved the fulcrum the opposite direction? It would take more force, or in this example, a heavier weight to lift the object!

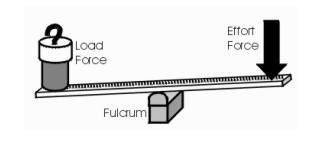

When talking about levers, things can get a little confusing, so there are a few terms we can use to help keep things straight.

In our experiment above, the heavy object we were trying to lift is called the load force.

The lighter weight we used to lift the load force is called the effort force. When the fulcrum was in the middle of the lever, the effort force had to be greater than the load force in order to lift the load force up.

But, by simply changing the pivot point of the lever, we were able to use a smaller effort force to lift the greater load force.

That is the beauty of levers – making work easier by lowering the amount of force that is required to lift or move something!

For further study, try these:

- Simple machines science projects

Simple Machines Science Lesson

Introduction to Simple Machines

Simple machines make work easier by multiplying, reducing, or changing the direction of a force.

The scientific formula for work is w = f x d, or, work is equal to force multiplied by distance.

Simple machines cannot change the amount of work done, but they can reduce the effort force that is required to do the work!

As you can see by this formula, if the effort force is reduced, distance is increased.

There are six types of simple machines: pulleys, wheels and axles, inclined planes, levers, wedges, and screws. Wedges and screws are both a type of inclined plane; pulleys and wheels and axles are both a form of lever.

An inclined plane is a board or other flat surface set at an angle to the horizontal. Since the force needed to push an object up an inclined plane is less than the force needed to lift the same object, inclined planes reduce the amount of force necessary to do a job. A ramp is an example of an inclined plane.

A wedge is shaped like two inclined planes placed back to back. Its sides slant down to a point, so that it can be driven into an object by an effort force. An axe is an example of a wedge.

Screws are basically an inclined plane wrapped around a middle section. The more “threads” (twists) on a screw, the less force required to drive it into something.

You might want to allow your children to experiment by driving different types of screws into a board. Discuss with them which screws are easiest to turn, and explain how the number of threads and the diameter of the screw affects this.

Levers are a bar or board that turn on a fixed support called a fulcrum. Levers raise and lower an object as force is exerted upon the lever. An example of a lever is a bottle-opener: the handle acts as a lever arm, and the pivot that fits under the rim of the cap acts as a fulcrum.

A pulley is a wheel with a grooved rim that is used to reduce the amount of force and change the direction of force needed to do work.

Pulleys are modified levers; their fulcrum is at their center.

A fixed pulley is used to change the direction of force needed to do work; in order to hoist up a load with a pulley and rope, force is exerted downward on the rope. Since it is easier to pull down using your own weight than to pull upwards, fixed pulleys are commonly used.

A moveable pulley is attached to a load and is used to reduce the amount of force needed to do work. It slides along a rope, rather then a rope sliding along it.

A block and tackle is a combination of fixed and moveable pulleys, and is used to both change the direction and the amount of the force needed to do work.

An example of a wheel and axle is an old-fashioned well, where a wheel is turned in order to crank the connected axle around, and the rope that the water pail is attached to then wraps around the axle.

A wheel turns because of effort force and resistance pushing against it; the force can be exerted on either the axle, or the wheel.

The example of an old well is a case of the force turning the wheel. An example of the force being applied to the axle is on a Ferris Wheel: the wheel spins because of the force on the axle.

The term mechanical advantage is used to describe the number of times a simple machine multiplies the effort force applied. The mechanical advantage is the ratio of the load force to the effort force, or, MA= F load ¸ F effort. This ratio gives an idea of the effectiveness of a simple machine in reducing work.

All more complex machines use at least one form of simple machine. A good activity for demonstrating this is to look at some common household machines with your children, and see if they can identify any of the simple machine parts.

The screw and the wheel and axle on a hand powered drill, and the screw and lever on a car jack, are examples of simple machines that are used in more complex ones.

How to Make Levers

A lever is a board or a bar that turns on a fixed support called a fulcrum. Fingernail clippers are an example of levers. The force exerted on the handle of the clippers compresses the blades of the clippers so that they trim the fingernail.

You might want to look at a pair of clippers with your children, and see if they can identify the fulcrum (the pivot joint between the two parts, in this case).

There are three types of levers: first, second, and third class.

Nail clippers are first class levers. You can make your own first class lever, using a ruler with a pencil to work as the fulcrum.

Center the ruler over the pencil, and set a small object or weight (this is called the ‘load’) on one end of the ruler. When you push on the opposite end of the ruler (the force you exert is called the ‘effort’), the weight is lifted.

You might want to mention other types of first class levers to your children; a seesaw is one example.

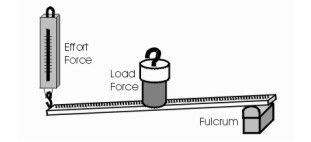

A second class lever has the load located in the middle of the ruler, with the fulcrum on one side and the effort on the other.

Using a spring scale that measures in newtons, you can identify the mechanical advantage.

If you have not already done so, you will need to find the weight of your load. Hook the load onto the spring scale, and record the weight in newtons.

Next, set the ruler (‘lever arm’), fulcrum, and load into position so that you form a second class lever. The lever arm should have one end resting on the fulcrum, with the load placed at the center of the lever arm.

Hook the spring scale to the lever arm at the end that is opposite the fulcrum, then pull up on the spring scale to lift the load. Record the effort force required to lift the load.

To find the mechanical advantage of your lever, divide the weight of the load by the effort force that was required to lift it.

For further study of second class levers, you might want to also measure the length of the lever arm (ruler) from the fulcrum to the load, and from the load to the spring scale.

Use the spring scale to act as the effort force again. After you have repeated this step several times, changing the position of the load and measuring it each time, analyze your results.

Does the effort force required to lift the load change when the load is moved closer to the fulcrum?

You should be able to observe that the effort force is reduced as the load is placed closer to the fulcrum. This is because the mechanical advantage increases as the distance between the load and fulcrum decreases.

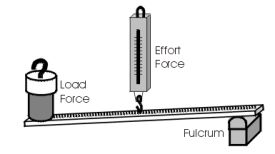

Third class levers have the effort located between the fulcrum and the load.

To experiment with effort force reduction, set up your lever with the fulcrum on one end and the load on the other.

The spring scale will be used in the middle. Discuss with your children whether they think the effort force will be reduced when it is moved closer to the fulcrum, or further away.

As with the second class lever, pull up on the spring scale and record the effort force required (you will need to put your finger on the end with the fulcrum, to act as a pivot point).

Also measure the distance on the lever arm from the fulcrum to the load, and from the fulcrum to the spring scale.

Repeat the process several times, moving the effort closer to and further from the fulcrum.

When you are finished, analyze your results. How did the effort force change when it was moved closer to or further from the fulcrum?

The effort force that is required to lift the load is reduced as the effort location is moved away from the fulcrum.

Wheels and Axles

Wheels and axles, such as those on carts, reduce resisting force by distributing it throughout the wheel or axle, and therefore make it easier to haul loads.

You can demonstrate to this to grade school age children using a Hall’s cart or small toy car and a weight or some other object to be the load.

First, try to push the load across a smooth surface. Explain to your children that there is some resistance, created by frictional force between the surface and the object.

Next, set the load on the Hall’s cart or toy car (you may need to use a rubber band to keep it on), and push it across the same surface.

What happens? There is much less resistance, since the only part of the cart that is touching the surface is its wheels.

The pressure exerted on the cart is distributed through the wheel and axle, rather than just between the surface and load.

You might want to look around your house for examples of wheels and axles.

Thing like roller skate wheels, bicycle wheels, and the gears in clocks are all examples of wheels and axles. Doorknobs are another example.

The rod (axle) that opens the door would be very difficult to turn if the knob (acting as a wheel in this case) was not connected to it.

Not all doorknobs are round-some look more like regular levers-but they function in the same way. You might want to explain to your children how each wheel and axle works; have them identify the axle and what causes effort force to the wheel and axle.

The formula for finding the mechanical advantage of a wheel and axle is the ratio of the radius of the wheel to the radius of the axle.

Thus, if you have a wheel that is 10 inches in diameter and an axle that is two inches in diameter, the radius of each will be half of that. The mechanical advantage will be a ratio of 5:1, or simply five.

Inventions: Archimedes Screw

What is an Archimedes Screw? It is a pump made with a screw inside of a tube, with a rod down the center of the screw, placed at an inclined angle in water.

By turning the screw, the water is drawn up through the tube.

The Archimedes Screw was documented as being in use in Egypt for irrigation purposes as early as 100 BC. The Archimedes Screw has been powered manually, by horses, engines, and even by windmills!

Throughout history, and up through modern times, it has been used primarily for irrigation and drainage purposes.